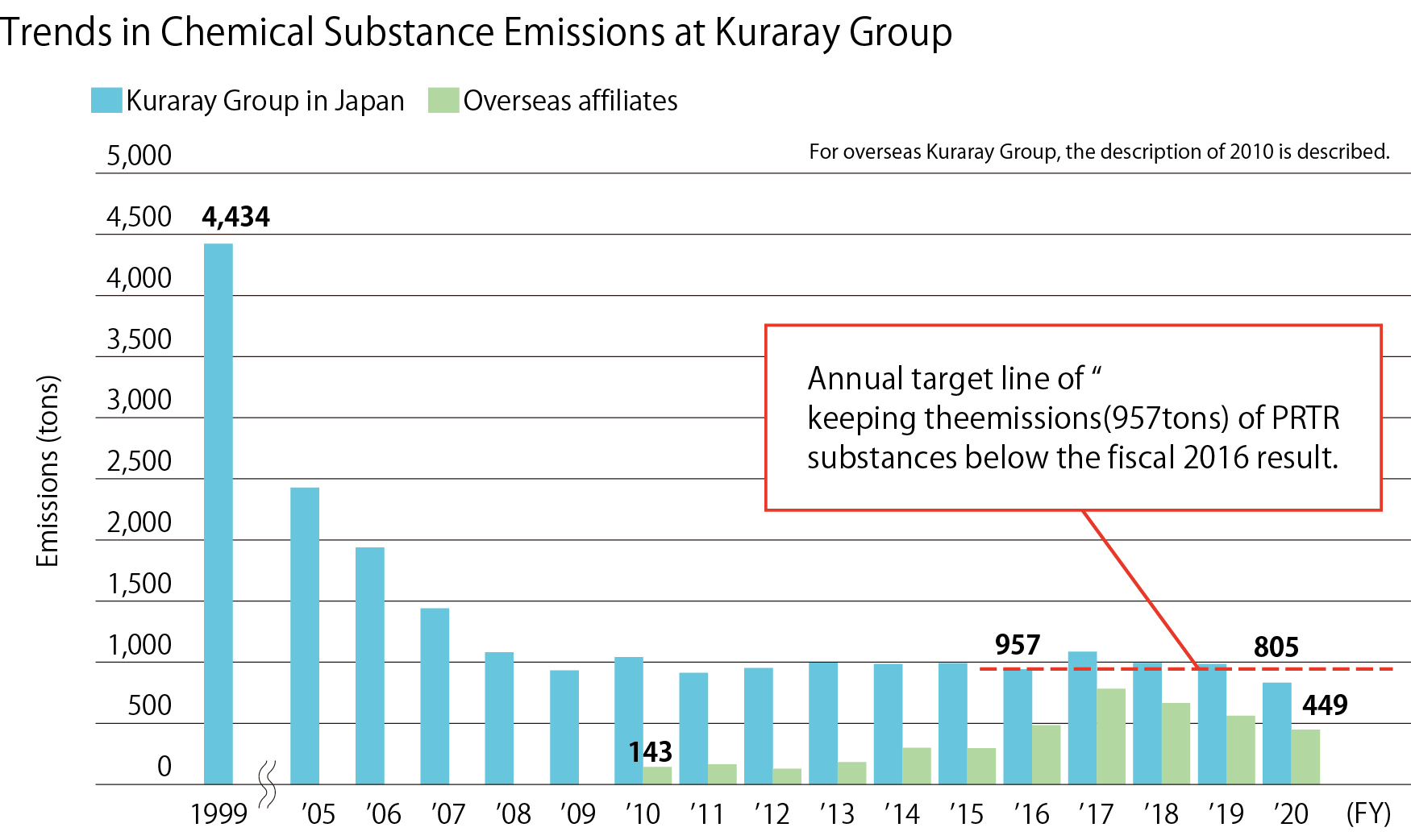

The Kuraray Group in Japan had made a major capital investment by around 2008 to reduce chemical substance emissions, and has achieved about an 80% reduction compared to fiscal 1999. Since then, we have set limits on the amount of Japan Chemical Industry Association (JCIA)-designated Pollutant Release and Transfer Register (PRTR) substances* based on the concept that even if the scale of business expands, the environmental impact outside the production sites will not be increased from the base year. To achieve this target, when we consider construction of new production facilities, we examine and carry out investment projects with consideration of measures to prevent an increase in chemical substance emissions. In fiscal 2020, emissions by the entire Kuraray Group in Japan totaled 805 tons (742 tons into the atmosphere and 63 tons into water areas), achieving the target of less than 957 tons, partly due to reduced production caused by COVID-19. Going forward, we will continue to take measures to prevent further emissions outside of our production sites.

The annual policy of the Kuraray Group outside Japan is to continue to comply with the environmental regulations of the respective countries and regions where each production site is located and to conduct quantitative control. Until fiscal 2017, emissions were on an upward trend due to the incorporation of businesses and the construction and expansion of production facilities. However, emissions have been decreasing since fiscal 2018 due to measures such as the expansion of exhaust gas treatment equipment and the improvement of operational control. Emissions in fiscal 2020 were 449 tons, almost the same as the previous year.

※Substances subject to the PRTR Act and substances designated by the Japan Chemical Industry Association