Planet

Environmental Management

Kuraray’s Approach to Environment

We believe it is vital for the Kuraray Group as a specialty chemical company to provide the world with the products and services needed to realize a low-carbon and environment-friendly society, and to manufacture our own products with as little environmental impact as possible. Based on this philosophy, the Kuraray Group in its global manufacturing activities continues to conserve the environment, including the promotion of measures against global warming, reduction of chemical substance emissions, and effective use of resources.

Kuraray Group Environmental Policy

The Kuraray Group has established the Kuraray Group Environmental Policy, and is promoting environmental conservation activities. Based on the Kuraray Group Environmental Activity Management Rule, these activities are carried out for constant improvement in the P (plan) D (do) C (check and evaluate) A (act and improve) cycle in cooperation with Kuraray plants / subsidiaries and the head office. Those plants and subsidiaries have acquired ISO 14001(Environmental Management Systems) certification and are steadily operating ISO 14001 systems.

Kuraray Group Environmental Policy

The Kuraray Group has established the following policy to contribute to the sustainable development of society and fulfill its responsibilities to future generations through business activities in harmony with environment.

Basic Policy

- We give maximum consideration to the environment in conducting our business operations.

- We conduct perpetual environmental improvement activities.

- We develop technologies and products which contribute to improvement of the environment.

Guiding Principles

- Reduce greenhouse gas emissions

Actively promote the improvement of energy efficiency, fuel conversion, and the utilization of sustainable energy such as biomass fuel. Continuously engage in the reduction of greenhouse gas emissions. - Reduce emission of hazardous chemicals into the environment

Promote replacement with less hazardous chemicals and continuously reduce emissions, and strive to minimize the emission of hazardous chemicals into the air, water, and soil. - Reduce the volume of waste

Promote reduction, reuse, and recycling of waste, and strive to minimize the volume of waste resulting from business operations. - Promote efficient utilization of water resources

Recognizing that water is a limited resource, strive to minimize the amount of water necessary for business operations by promoting the optimization of operation conditions and recycling. - Develop and provide environmental improvement technologies and products with low environmental load

Strive to develop and provide technologies that reduce the environmental load throughout the entire lifecycle, and contribute to the environment. - Reduce environmental load in procurement (raw materials, supplies, and equipment) and logistics

Strive to procure environment-friendly materials, supplies, and equipment, while at the same time reducing the environmental load in the logistics process (transportation and storage). - Consideration to biodiversity

Give maximum consideration to biodiversity, and strive to preserve biodiversity and engage in the sustainable use of biological resources. - Proactively disclose environmental information and promote dialogue with society

Proactively disclose corporate information regarding the environment (including risk information), and promote dialogue with the local community and society as a whole in order to build mutual understanding and trust. - Increase employee awareness of the environment and improve the level of environmental management

Increase employee awareness and understanding of the environment through training and internal communications. Improve the level of environmental management by deploying environment activity management systems and environmental accounting.

Environmental Conservation Management

In 2024, the Kuraray Group experienced minor problems such as temporary exceedances of regulation values and an incident reportable to the relevant authorities (environmental accident*) in Kuraray Group outside Japan. However, there were no major leak accidents of hazardous substances and waste that caused severe damage to the environment. For environmental accident that did occur, we strive to prevent recurrence by identifying the root cause, including background factors, discussing countermeasures based on these findings, and by continuously following up on the implementation status of these measures. The Kuraray Group in Japan strictly observes statutory effluent standards for emissions into the atmosphere and public waters, and there were no incidents causing a significant impact on the atmosphere, rivers, underground water, marine water, soil, and so on. For waste containing polychlorinated biphenyls (PCBs), which are hazardous waste and are mandatory to be detoxified, we properly consign detoxification to waste disposal company in accordance with the Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes (PCB Special Measures Act). The Kuraray Group outside Japan also manages the amount and quality of waste gases and wastewater in accordance with the laws and regulations of the countries and regions where our production sites are located.

*In the Kuraray Group, cases reportable to the relevant authorities are counted as "environmental accidents" according to company regulations.

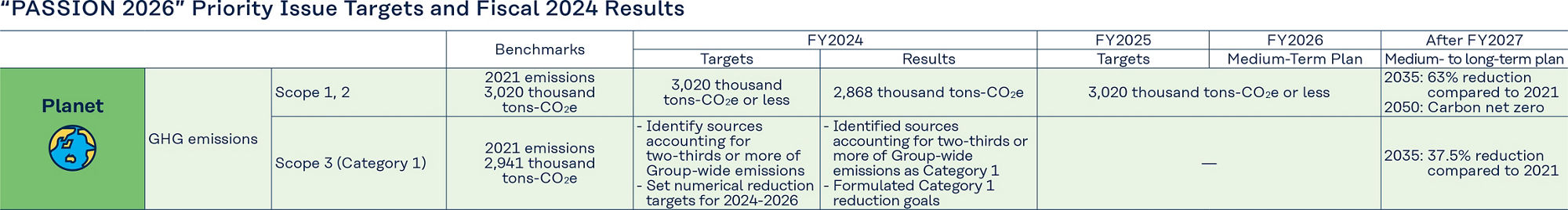

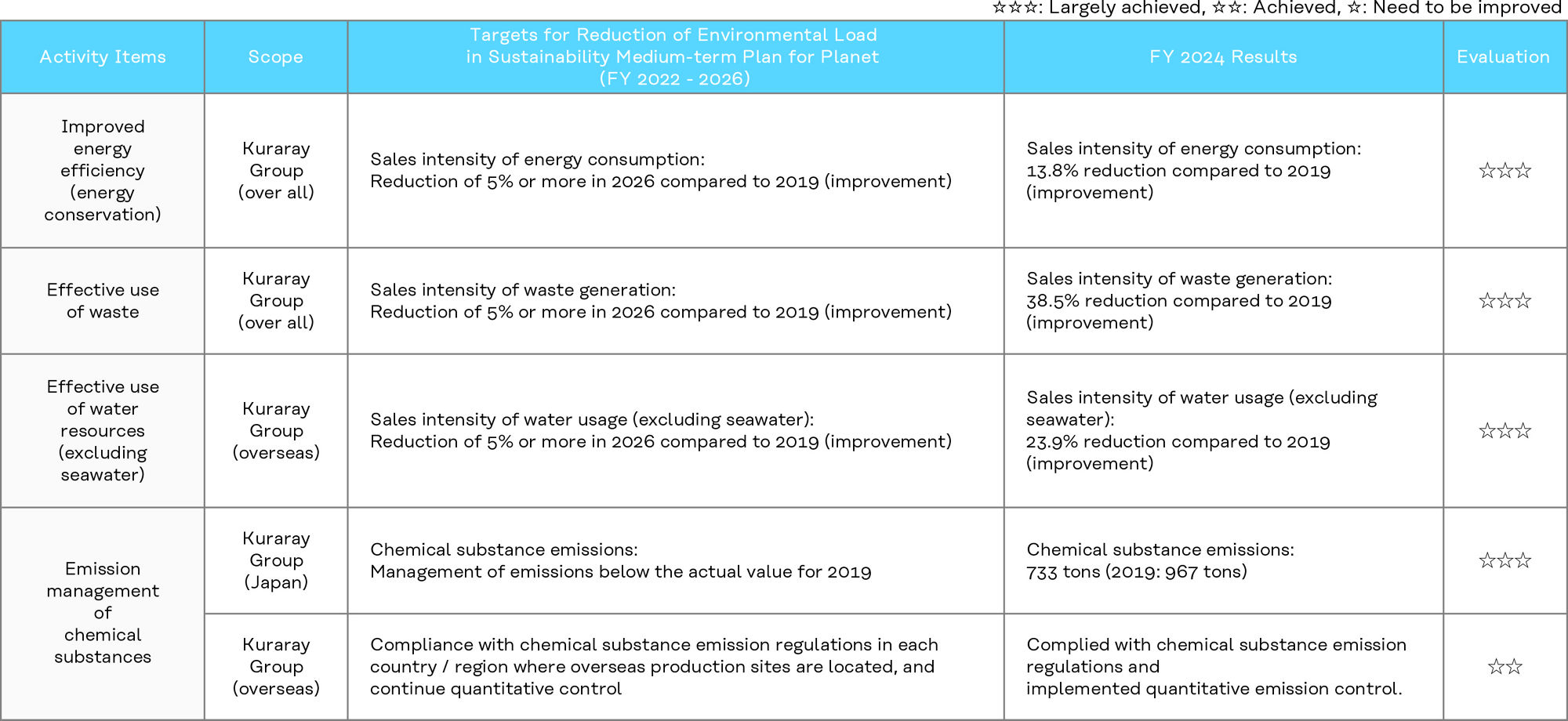

Targets for Reduction of Environmental Load in the Sustainability Medium-Term Plan for Planet and Results in 2024

The Kuraray Group set targets for reduction of environmental load in the Sustainability Medium-Term Plan for Planet which began in 2022 and conducted activities accordingly. Specific numerical targets and results in 2024 are shown in the table below.

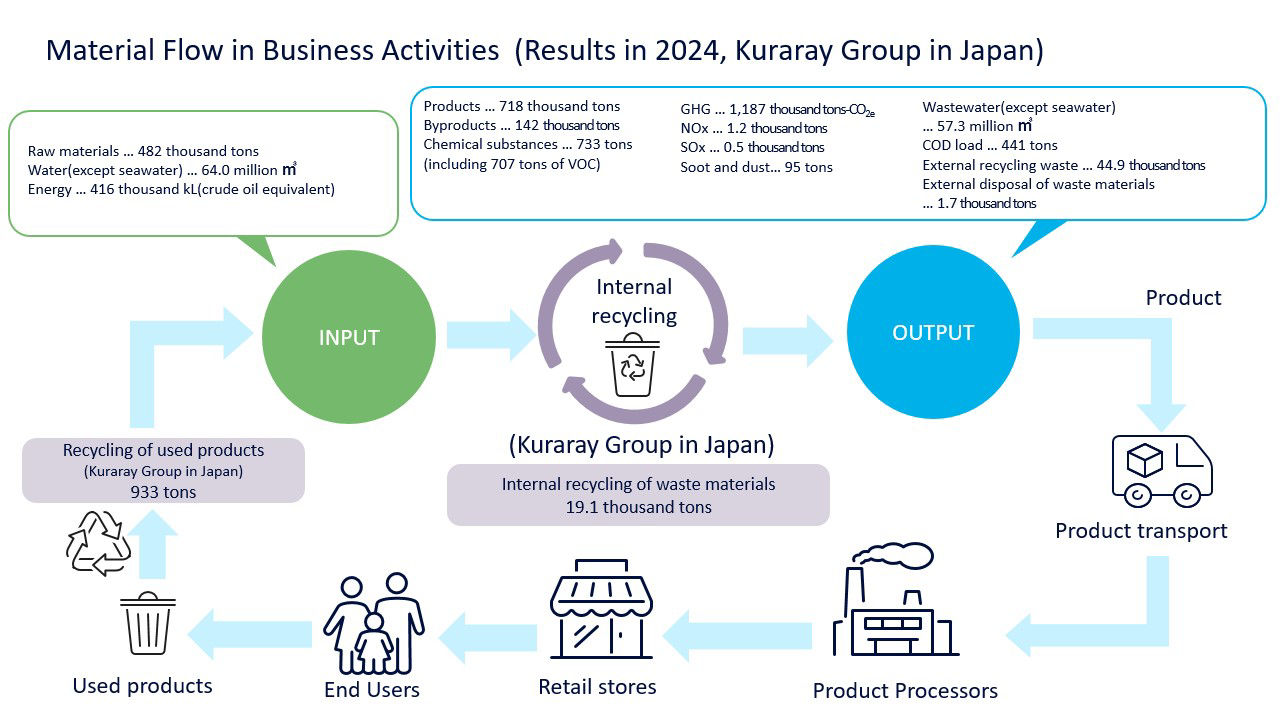

Material Flow in Business Activities

The Kuraray Group uses large amount of energy, chemical substances and water resources required for its business activities. We conduct quantitative surveys on the used raw materials, resources, products supplied outside the Group and emitted substances every year to help reduce the environmental load associated with our business activities.

Collaboration with industry associations

The Kuraray Group has joined Japan Chemical Fibers Association (committee member), Japan Chemical Industry Association, Japan Petrochemical Industry Association, and Japan BioPlastics Association to enhance our environmental management efforts, and engages in a broad range of activities, such as reduction of GHG emissions, energy conservation, reduction of chemical substance emissions, and prevention of marine plastic pollution, in cooperation with the industry in order to address global environmental issues.