People

Kuraray’s Approach to Safety

In the Kuraray Group’s business activities, safety is the cornerstone, an absolute requirement that forms the basis for all activities. It is evident that realizing workplaces where people can safely work at ease without accidents is a critical theme both in maintaining a stable supply of products and in maintaining society’s trust.

With these concepts in mind, the Kuraray Group has established and implemented a safety management system to undertake various activities. A number of initiatives are being promoted to raise the safety awareness of our employees and to have safety behavior and confirmations established as common practice at work.

At each workplace, we uncover risks related to occupational safety and process safety, conduct thorough risk assessment activities, promote fundamental equipment safety measures, and prevent process accidents and occupational injuries. Additionally, to prepare for the event of an accident or injury, we are carrying out training to minimize damage, sharing information on cases of accidents and lessons learned, and horizontally deploying countermeasures.

Guiding Principles for Ensuring Safety

Safety is the Cornerstone of Everything We Do

Action Courses for Ensuring Safety (FY2025)

- Practice Safety First, Production (Construction, R&D) Second

- Practice “Prediction Hazards”, “Make Sure” the Safety Comes Before Taking Action, and “Confirm” If the Action Results are What You Expect

- Every Individual and Every Department (Every Leader/Manager, Every Team) Shall Be Aware of Safety as “Their Responsibility” and Act Appropriately

Safety Activity Management

In accordance with the Company's Safety Activity Management Regulations, the Kuraray Group develops a safety plan every year and implements it to ensure occupational safety and process safety. At the Safety Promotion Committee attended by the President and executives in charge, we make an overall assessment and have a discussion on safety activity performances of the current year and establish an activity policy for the coming fiscal year. This policy is reflected in and implemented through specific action plans of each plant and department. A group of safety representatives from headquarters, including executives in charge of safety, visit every plant of the Group in Japan twice a year to examine their management of implementation progress. In addition, staff members from headquarters visit the Group subsidiaries outside Japan once every three years to confirm their status as well as conduct examinations via remote conferencing. We perform an overall assessment of results based on the issues found through the surveys made at each plant, the safety results for that year, and other factors. We incorporate this assessment into the formulation of company-wide policies for the next year, thereby operating a management system for safe operations.

Priority Activities for Occupational Safety, Process Safety

| 2024 | Safety Activities in 2025 | |

|---|---|---|

| Activity | Performance | |

| Practice of basic action for safety (prediction hazards, confirmation, etc.) on actual workplaces | We believe our efforts to instill the habits of “prediction hazards” and “confirmation” have achieved some positive effects. However, the degree of practice in the workplace varies. Cases of accidents and injuries caused by skipping basic actions, such as forgetting to close valves, continue to occur. Continuous efforts are needed to enable every employee to perform basic safety actions in every situation. |

|

| Understanding / Identifying risks in actual workplaces and considering countermeasures from the facilities and management aspects | We have identified and improved risks in actual workplaces through activities such as “5S” to better organize workplaces, sharing "awareness" discovered in the workplace, and reviewing the operation standards. However, risks that have become commonplace and unnoticed still remain. Due to the assumption that ‘such things will not happen,’ these risks are often excluded from consideration, leading to safety measures that rely heavily on human attention and skill, resulting in accidents and injuries. Moving forward, it is necessary to continue to identify serious risks that may lurk at workplace and implement safety measures from both the equipment and management perspectives. | |

| Ensuring safety of construction and maintenance works | To ensure safe construction and maintenance work, we review systems and regulations and provide training. In particular, as a result of the implementing safety measures to provide safe workplaces, conducting on-site, in-situ tripartite checks at work sites, and appropriately communicating information, in advance, the number of work-related injuries at work sites due to inadequate provision of safe workplaces has decreased. It is necessary to ensure that the rules for ensuring safety are operational and practiced on-site. | |

| Improving the level of process safety management at overseas chemical plants | We have continued to conduct safety audits for overseas chemical plants in the U.S., Europe, Asia, etc. Through the continuous operation of the system of safety policy briefing meetings and accident reporting meetings, etc. introduced in 2023, we have improved communication with our overseas groups. In addition, the global team of experts in process safety management (PSM), consisting of cross-organizational members, conducted on-site audits at three locations in the U.S. to assess the implementation of safety management system. They identified several issues and are working on addressing them. We will continue to improve the level of safety management. | |

Process Safety

At the Kuraray Group, we consider it our major responsibility to prevent the occurrence of explosions or fires, leakage of hazardous materials and other accidents that could have an immense impact on society, as well as to minimize any damage in the event of such occurrence. For this purpose, we have continuously undertaken activities such as risk assessment related to process safety, and we strive to take earthquake and tsunami countermeasures for buildings and plants, and organize the safety management system for facilities.

After accidents occurred at the other companies in the 2010s, we are paying particular attention to the risk assessment of unusual tasks and situations such as the starting and ceasing of an operation, a power and water outage, and an emergency shut-down. Moreover, we also extract various risks that may arise in the event of a failure of safety equipment or incompliance with standard procedures or rules and consider countermeasures.

Additionally, we are also working to diverse equipment and management systems and develop human resources to respond quickly to an unusual situation before an accident occurs through educating members to raise their sensitivity to risks in order to detect any sign of abnormalities and to clarify standards to determine an unusual situation.

Employees are regularly trained through on-site drills on various situations including the night time, holidays, when managerial personnel are absent and situations that occur without notice, in a drill using an external facility or a joint drill with a local fire department. We are engaging in initiatives for receiving evaluations from an external organization about our safety-related foundations and culture, and we aim to be a safe company that does not suffer any accidents by operating the PDCA cycle with a thorough understanding of which areas need further reinforcement.

In the event of a significant accident, an Emergency Command Center led by President is ready to be established to promptly respond to the situation and provide on-site support. Media training is also provided to key managerial personnel in charge of public relations to enable them to appropriately provide information to the regional community and media in case of such an accident.

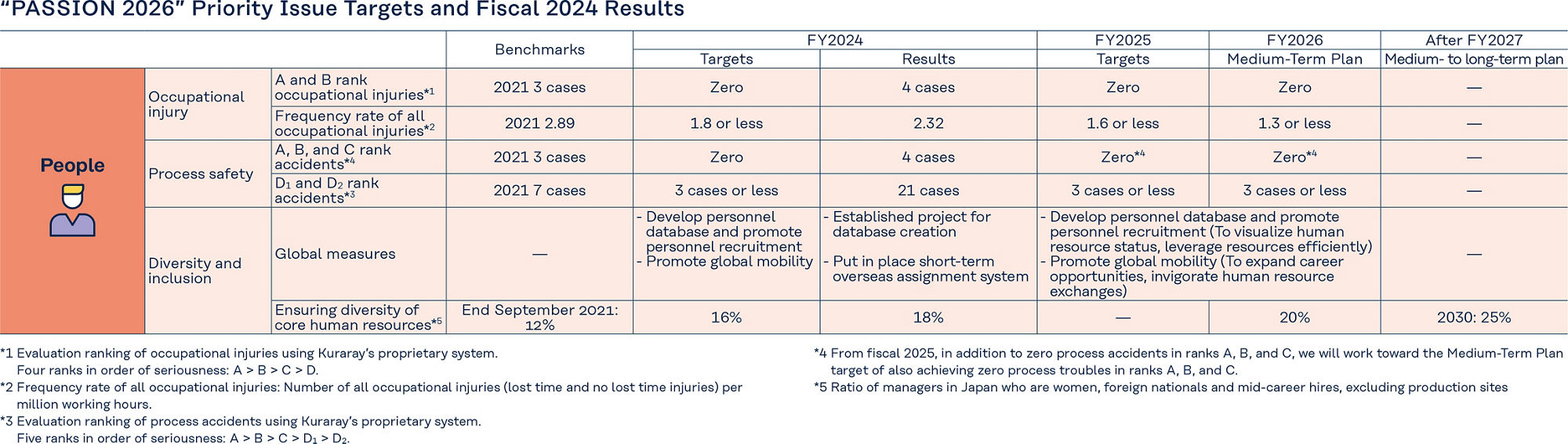

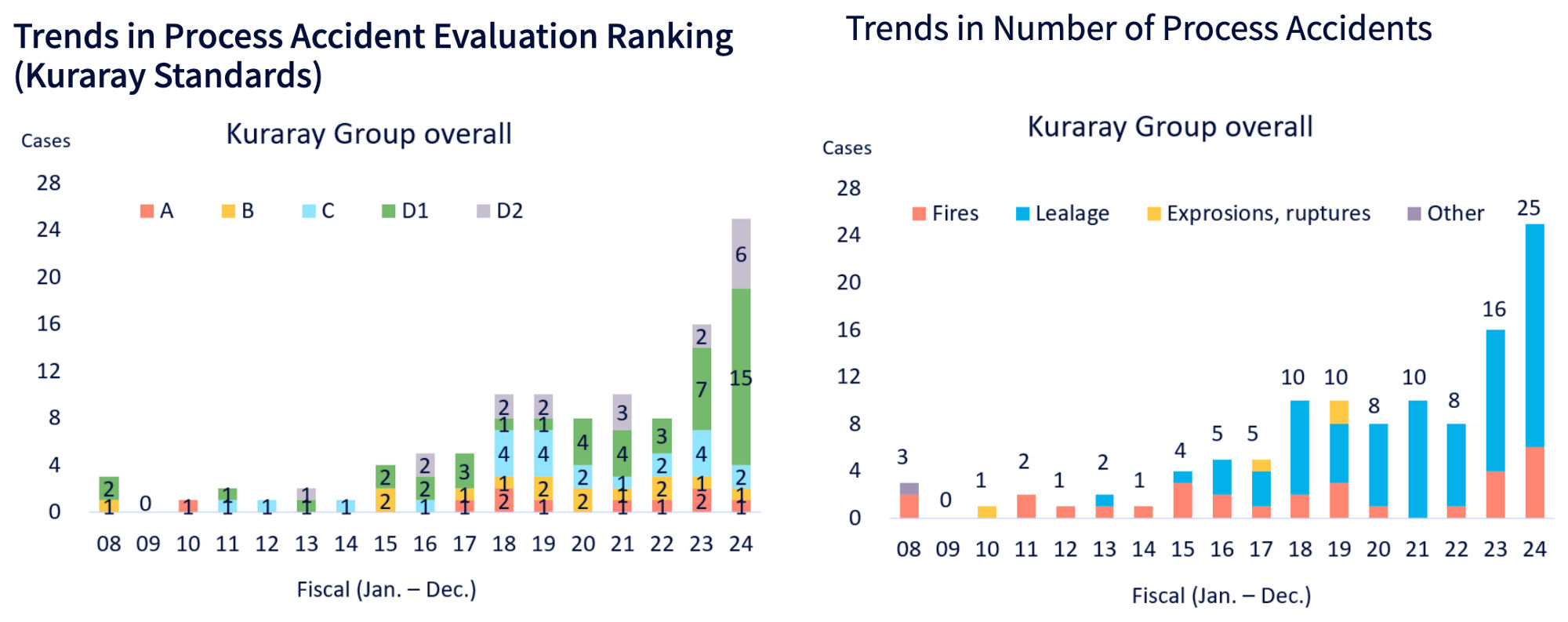

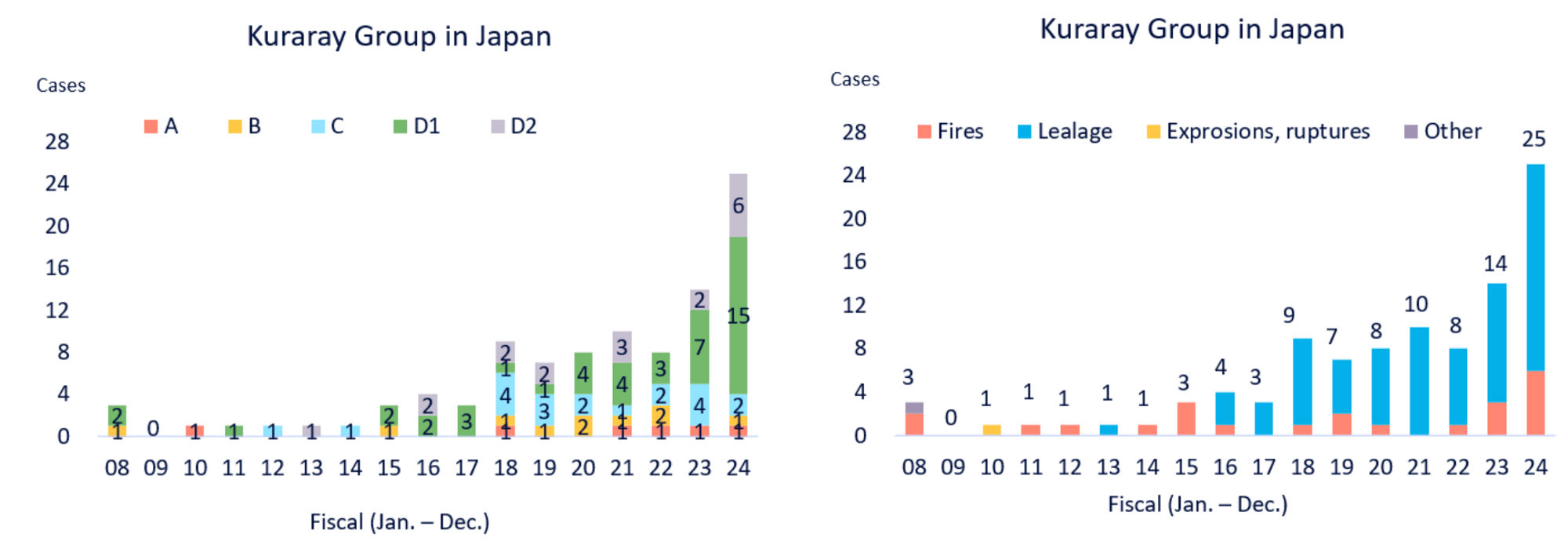

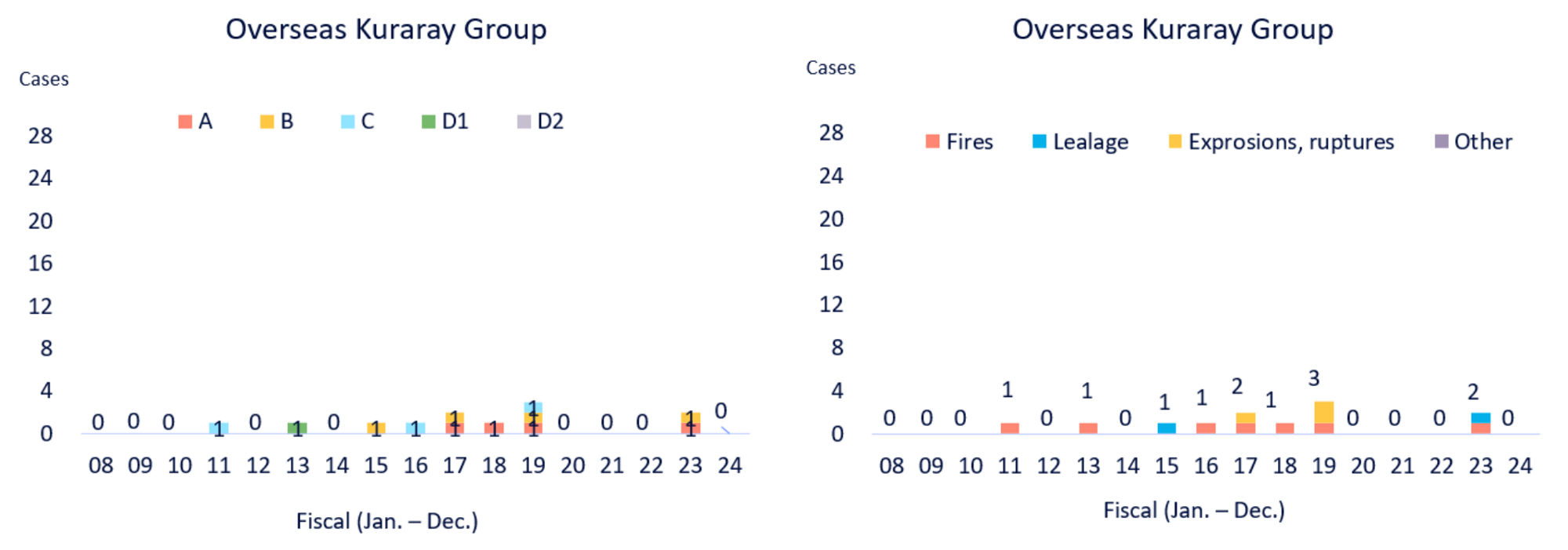

In 2024, the Group-wide total of A, B, or C rank accidents, which are classed as relatively serious process accidents according to our in-house standards, was four (Group companies in Japan: A rank: one case of leakage, B rank: one case of leakage, and C rank: one case of leakage and one of fire). We thus did not meet our target of zero accidents. The total of A, B, or C rank accidents at Group companies in Japan has now stayed around the level of five per year for several years. Overseas Group companies experienced no accidents. In 2024, the Group-wide total of D1 and D2 rank accidents, which are cases classed as minor by our in-house standards, such as leakage of a very small amount of hazardous material and fires or ignition that are quickly put out, was twenty-one (Group companies in Japan: D1 rank: eleven cases of leakage and four of fire, D2 rank: five cases of leakage and one fire; overseas Group companies: none). This result fell short of our target of three or less. The number of process accidents increased this two years and was the worst figure on record. We believe that the increase in the number of process accidents is partly since even very minor leakage cases are now being reliably reported and managed. However, we have also observed accidents caused by insufficient checks before and after operations, such as forgetting to close a valve, overlooking risks due to the normalization of on-site risks, and cases due to the aging of equipment. We are addressing these issues accordingly. We are working to address this and will continue to identify workplace risks and measures to address them, targeting zero relatively serious process accidents and a reduction in the number of minor troubles.

In the Kuraray Group, incidents related to safety such as fires, explosions, and leaks that require reporting to supervisory authorities are classified as process accidents. Incidents that do not qualify as process accidents but were judged to have the potential to lead to one are classified as process troubles. The number of process accidents in the overseas group is lower compared to the domestic group because the criteria for reporting to supervisory authorities differ between domestic and overseas locations. As a result, incidents of the same severity were counted as process troubles in the overseas group. Therefore, in addition to our existing goal of zero ABC-ranked process accidents (our unique evaluation method) for safety and disaster prevention, we will add the goal of zero ABC-ranked process troubles starting from 2025. We will continue our efforts to reduce both process accidents and troubles across the entire Kuraray Group.

In addition, while continuing the safety audits for overseas chemical plants that began in 2019, we formed a new team of global experts in Process Safety Management (PSM) and commenced activities in 2022. The purpose of this expert team is to identify and grasp issues by its cross-organizational members, share information on findings for improvement, and horizontally deploy the findings throughout the Kuraray Group. In 2024, we conducted on-site audits of the safety management practices at three locations in the U.S., several issues were identified, and are addressing each of them accordingly. We will continue to thoroughly prevent the recurrence of process accidents at our overseas chemical plants. Additionally, we will maintain PSM audits and address the issues identified through these audits and other means to improve the safety management level.

Occupational Safety

Realizing that the safety and health of its employees are the basis of business activities, the Kuraray Group aims to create safe and injure free workplaces by striving to enhance the safety level of each of its employees and organizations. Through Group-wide policies and activity items including Guiding Principles and Action Courses for Ensuring Safety, policies and plans are thoughtfully developed and put into practice according to each plant’s and division’s situations and their unique ideas. Safety activities and their challenges are discussed among workers and employers at the Safety and Health Committee held by each of the domestic plants and factories every month, aiming to realize workplaces where people can safely work at ease without accidents.

We continuously promote activities to reduce serious occupational injuries caused by equipment deficiencies through risk assessment activities and essential safety measures for equipment. However, many occupational injuries caused by individuals’ unconsidered or unconscious behavior have still occurred. Therefore, education to raise the sensitivity of each employee to risks has been promoted to eliminate such occupational injuries.

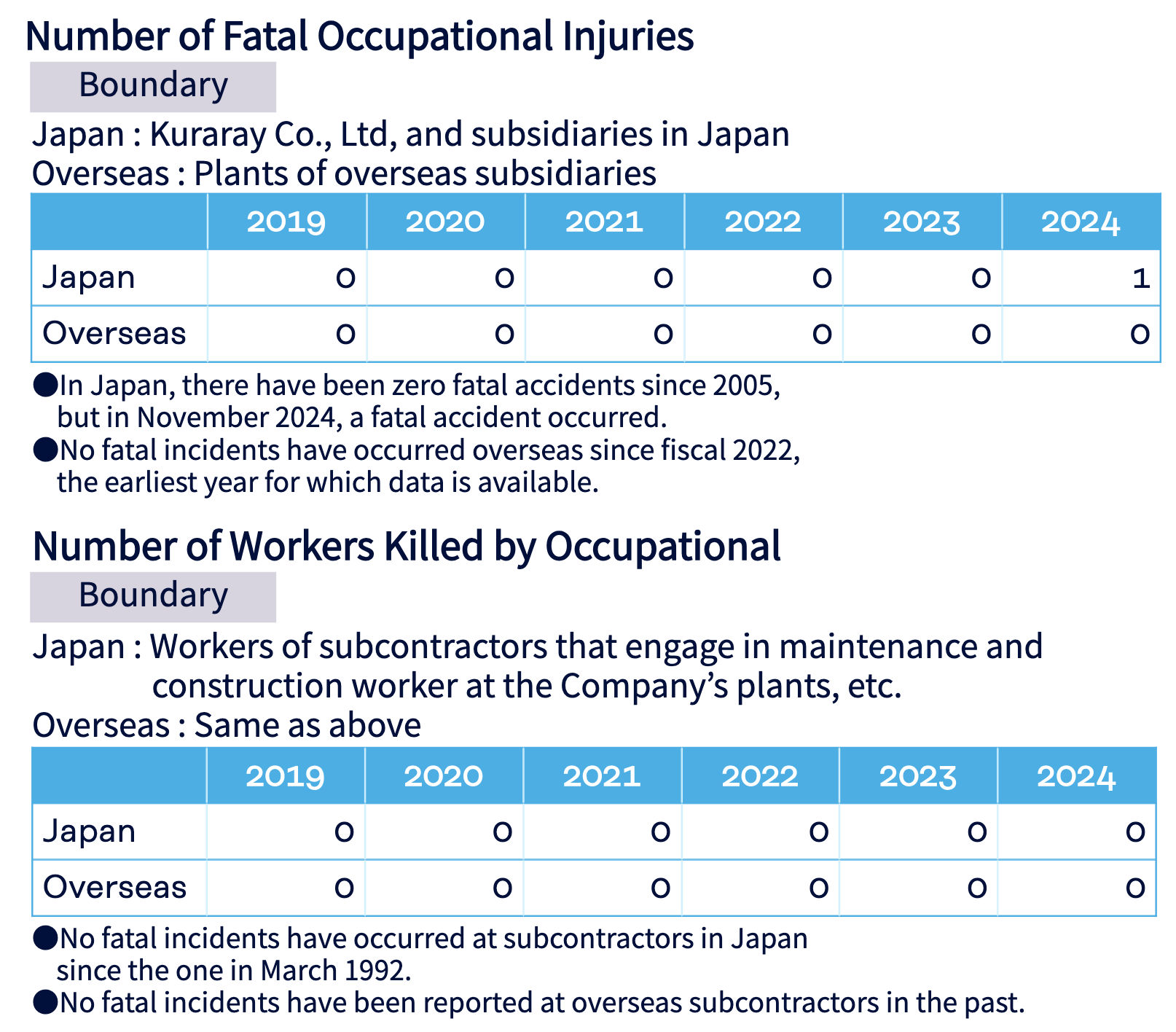

In November 2024, a fatal accident occurred at the Kuraray Group in Japan. The fatality occurred when a flexible container temporarily placed in a two-tiered stack by the worker himself collapsed and was caught between the flexible container and the steel brace of the building, causing the worker to die from compression asphyxiation. The accident was directly caused by unloading and double-stacking flexible containers in excess of the quantity specified in the work standards, and an accident reporting meeting was held to discuss how to prevent recurrence, including the background factors that triggered such behavior. We will use this fatal accident as a wake-up call to take action to prevent such serious industrial accidents from happening again at all Kuraray Group workplaces.

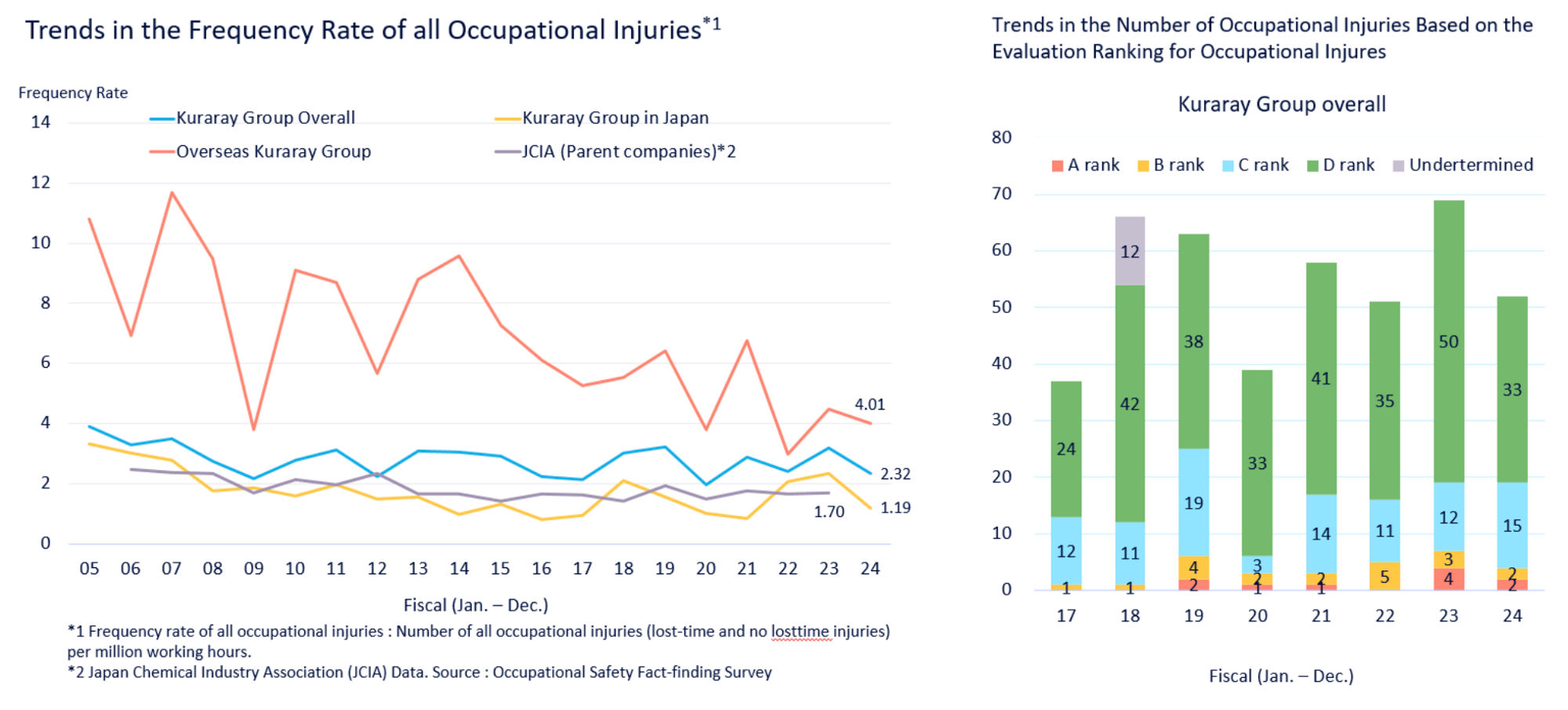

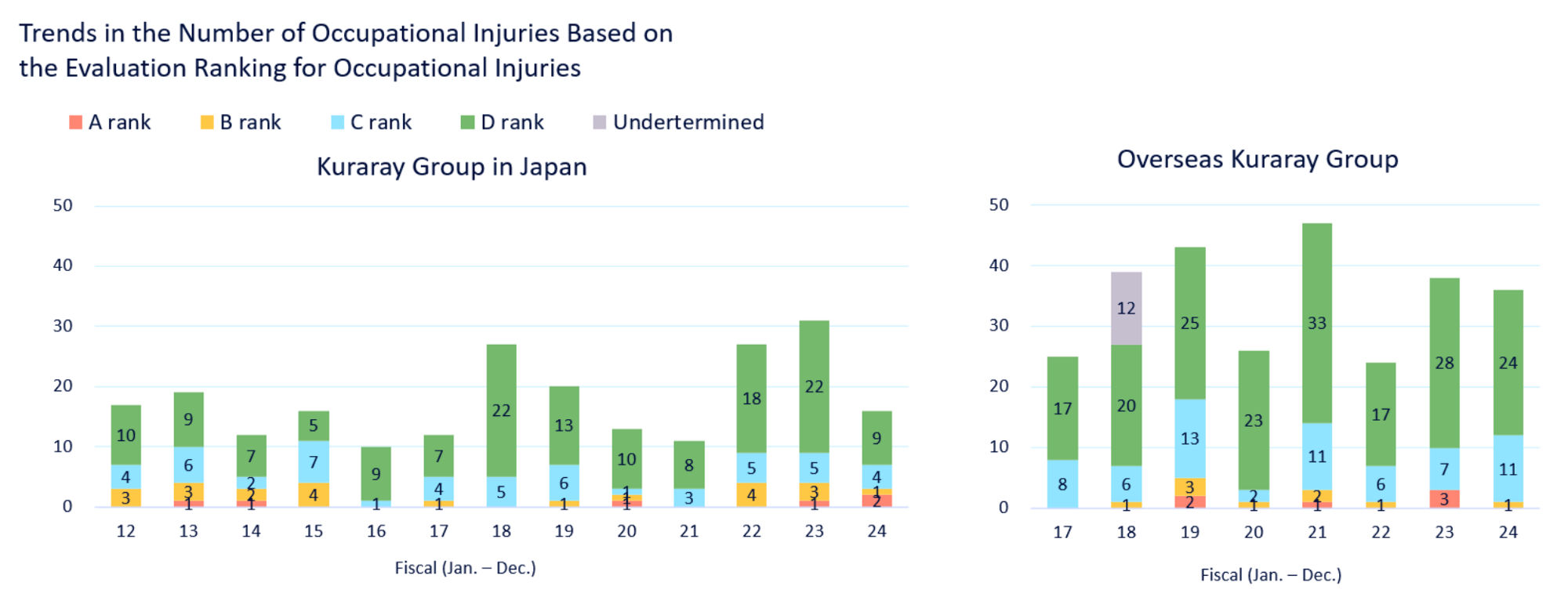

The frequency rate of all occupational injuries for the entire Kuraray Group in 2024 was 2.32 (1.19 for the Japan group and 4.01 in for the overseas group), falling short of our target rate of 1.8 or less. The Japan group fell far short of our target rate of 0.6 or less, but the figure was almost halved from the previous year. The overseas group also slightly short of the target rate 3.8 or less, but we have determined that the rate of all occupational injuries has decreased from the previous year and has been declining year by year. We have introduced a unique index to assess the severity of occupational injuries using a four-level ranking, from A to D. Our target is to achieve zero occurrence of the more severe A and B rank occupational injuries. There was a total of four A and B rank occupational injuries across the Group in 2024 (two A rank and one B rank injuries in Japan, and one A rank injury overseas), a result that fell short of the target. The A and B rank injuries included one case each of being caught by heavy objects, entangled in machinery, contact with hazardous substances such as liquid exposure, and falling. The causes were a failure to identify risks and insufficient measures for safety that rely on human attention and skill, which we are now addressing. We are steadily implementing initiatives to deal with related issues as we continue to work toward safe, injury-free workplaces.

Risk assessment of new business, capital investment, etc.

The Kuraray Group has in place and operates a system that carries out prior surveys and risk assessment regarding process safety and occupational safety and health of new projects and capital investments in and outside Japan through the functions of the Technical Evaluation Committee, the Technology Review Meeting and the Safety and Environment Examination to verify that safety measures and environment measures are sufficiently considered before moving to the next step. In addition, changes in raw materials, facilities, operating conditions and the organization as well as personnel transfer in line with the organizational change (supervisors, administrators, persons in charge, etc.) are implemented after taking measures required upon assessing risks as part of the change control process. The Kuraray Group ensures safety in introducing new business and facilities by steadily implementing these initiatives.

Investigation and Prevention Measures Concerning Fire Incident at U.S. Plant

In December 2023, we announced the results of an investigation into a fire incident that occurred in 2018 at a plant belonging to a subsidiary in the United States. The investigation examined the incident from three perspectives—technology, governance, and response to lawsuits—and put together recurrence prevention strategies in each of these areas, which are now steadily being implemented. Additionally, we compiled a Group-wide set of measures based on the results of the investigation and informed by the recurrence prevention measures, and are rolling these out horizontally across the Group through on-site safety checks and other activities. By extending these initiatives to Group companies in Japan and overseas, we are aiming to further reinforce safety and risk management frameworks across the Kuraray Group.

> Management Briefings

Safety Audits for Chemical Plants outside Japan

We initiated safety audits for chemical plants outside Japan in 2019 and we have continued to grasp process safety risks and review and strengthen safety measures to strive the safety and stable operation of the Group outside Japan. In 2024, safety audits were conducted on-site at our plants in the U.S., Europe, and Asia. In addition to following up on the status of responses to issues identified in the previous year’s safety audit, we check on the progress of identifying the causes of process accidents and troubles, as well as the progress of countermeasures to improve the safety level at the site. In 2022, we formed a global in-house team of experts in process safety management (PSM) and started our activities. In 2024, we conducted on-site audits of the safety management practices at three locations in the U.S. and are addressing the identified issues. We will continue these audits by the expert team to confirm the current status of safety management systems at overseas chemical plants, identify issues, and improve the safety management level.

Kuraray’s Proprietary Evaluation Method for Process Accidents

Up to now, the Kuraray Group set targets for process accidents by evaluating safety performance based on the number of accidents, regardless of their severity, including incidents such as fires, explosions, and leaks that require official reports to supervisory authorities. However, this method was insufficient for setting the appropriate targets according to risk. Accordingly, we tried to classify process accidents according to their size and include them in the evaluation rank. However, most of the process accidents that occurred within the Kuraray Group were classified as the lowest rank according to the generally used classification method (the CCPS method, etc.), which did not meet our objectives. In 2020, therefore, we developed a proprietary evaluation method. This evaluation method classifies the scale of an accident by the type of accident such as fire, explosion, leakage, etc., and determines rank by considering the presence or absence of human damage and factors that led to the occurrence of the accident, etc. The method also enables further sorting and classification of accidents with the lowest rank in the CCPS classification. In this way, we aim to eliminate major accidents that fall into the A, B, or C rank as “accidents that should never occur.” For minor accidents classified as D1 or D2 rank, including slight leakage of hazardous materials, fire, and ignitions extinguished by initial firefighting, etc., we set targets for each type of “accident that requires a reduction in the frequency of occurrence of risk,” and use these targets to carry out appropriate safety risk reduction activities in accordance with risk. From 2021, we have set annual targets for process safety based on this evaluation method and are implementing measures accordingly. Due to the criteria for process accidents being those that require reporting to supervisory authorities, incidents that do not require such reporting are managed as process troubles, which are incidents that do not qualify as process accidents but were judged to have the potential to lead to one. However, since the criteria for reporting to supervisory authorities differ between domestic and overseas locations, relatively significant safety incidents that occurred overseas were counted as process troubles and were not included in the reduction targets. Therefore, from 2023, we have applied the ranking classification method to process troubles as well, and from 2025, process troubles classified as A, B, or C rank will also be included in the targets, aiming for zero occurrences.

Evaluation and Classification of Occupational Injuries

Generally, categories based on the severity of injuries, including fatal injuries, lost time injuries and non-lost time injuries, are used as an indicator for occupational injuries. In particular, the frequency rate of lost time injuries is often used to assess the level of or establish a target for organizational safety. However, actual safety levels may deviate from the results of this assessment method for the following reasons:

(1) The severity of injuries is unpredictable in many cases.

(2) The occurrence factors of an injuries are not taken into consideration.

(3) (When it is applied to global management) criteria of determining the degree of injuries depends on the country.

In 2012, we therefore have established a proprietary evaluation and classification of occupational injuries by subtracting unpredictable factors and adding an assessment of occurrence factors. This quantifies not the actual severity of injuries but the potential severity of injuries that could have been caused by occupational injuries. Moreover, faults that caused such injuries are divided into human, equipment and managerial, rated numerically, and added to the potential severity of injury to determine the ranking from A, B, C to D.

As a result, the number of severe occupational injuries ranked A and B serves as an indicator for evaluating the level of organizational safety.