Progress Report on MICROFADE Development New ballast water management system using a special filter to be unveiled at SEA JAPAN 2010 exhibition, April 21-23

Kuraray Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo; President: Fumio Ito) today reported on the progress it has made toward the commercialization of the new ballast water management system that it announced in October 2009. Brief details are set out below.

Also, Kuraray will exhibit an actual filtration unit-the heart of the system-for the first time at the SEA JAPAN 2010 International Maritime Exhibition to be held at the Tokyo Big Sight Exhibition Center from April 21-23, 2010. The filtration unit will be exhibited in Booth No. J-07.

Status of Approvals

In line with the schedule shown in Table 1, below, Kuraray is steadily making progress in its preparations to obtain the approvals required for the commercialization of the new ballast water management system.

Status of Sales Network

Kuraray is working to complete the establishment of global networks for its sales activities and technical service offerings associated with the new ballast water management system prior to obtaining system approvals. To this end, the Company has entered into a basic sales agency agreement with Kashiwa Co., Ltd. (Headquarters: Minato-ku, Tokyo).

Status of Distribution Network

Kuraray is making progress with the establishment of an overseas network for distributing supplies and parts. To accelerate this process, the Company has concluded a basic business agreement with Fuji Trading Co., Ltd. (Headquarters: Naka-ku, Yokohama City).

Release Schedule and Sales Target

- As soon as it has obtained all the necessary approvals as scheduled, Kuraray will initiate sales of the new ballast water management system from October 2011.

- The market is expected to peak around 2015-2016. At that time, Kuraray is aiming to achieve annual net sales of the system totaling over ¥50 billion.

Trademark

Having named the system MICROFADE, the Company is now in the process of registering this trademark in 11 countries throughout the world, including Japan. The name is derived from the system's function, by which marine microorganisms such as plankton and bacteria fade away.

| Schedule | Approval |

|---|---|

| October 2010 | G9 Basic Approval |

| July 2011 | G9 Final Approval |

| October 2011 | G8 Type Approval |

- G9

- Approvals granted by the International Maritime Organization (IMO)

- G8

- Type approval granted by national authorities

* Image download service for the news media

We provide the ability to download images by clicking on them exclusively to the news media.

Please contact the Kuraray Corporate Communications Department if you wish to use this service.

- Key Features of MICROFADE

-

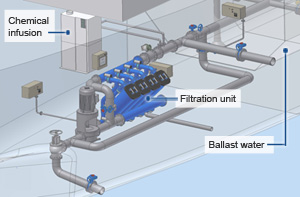

- Organisms are sufficiently removed during the front-end process through high-precision filtration that employs special filters. This makes it possible to substantially reduce the amount of active substances (chemical substances) used during the post process.

- Energy-saving operation is achieved due to Kuraray's special filters with low-pressure requirements,which enables the MICROFADE system to use existing power generators and ballast pumps.

- Compact design of the system's primary components (filtration unit and chemical infusion unit) allows for conserving space.

- Requiring neither precise temperature control nor a large-sized tank, the system also enables reduction in power consumption and conservation of space. These savings are due to the utilization of solid chemical agents that can be stored at room temperature.

- Seawater is drawn from overboard

- Seawater then enters the filtration unit

- Organisms removed by the filters are discharged

- Filtered seawater proceeds through the system

- Active substances automatically injected into filtered ballast water

The active substance is infused - To ballast tank

Disinfected seawater enters the ballast water tank

- Ballast pump siphons ballast water from ballast tank

Ballast water is drawn from the ballast water tank - Automatic measurement of residual chloride concentration, neutralizers automatically added as needed

Neutralizing agent is infused when the chlorine is too high - Ballast water discharged

Ballast water is discharged

- Ballast Water and Related Problems

-

- Ballast water, consisting of sea water that is drawn into a specialized tank in order to maintain balance on cargo ships, is often taken from a port in one country and discharged at a port in another. As a result, the disruption of local ecological systems after the introduction of foreign plant and animal species contained within ballast water has become an international problem.

- In response to this problem, the International Maritime Organization (IMO) adopted what is officially referred to as the International Convention for the Control and Management of Ships' Ballast Water and Sediments in February 2004. This agreement is scheduled to make mandatory the installation of ballast water treatment equipment aboard ships in near future.

- The agreement also stipulates that discharge standards will be applied to ocean-going vessels sequentially, depending on their year of construction and ballast tank capacity. These standards are expected to be applied to all ocean-going vessels by 2017 (applicable to newbuilds starting in 2011 and existing ships in 2015).

- Market for Ballast Water Management Systems

-

- Combining both newbuilds and existing ships, the market for ballast water management systems is anticipated to reach ¥2 trillion.

- Anticipating that market demand for ballast water management systems will start around 2012, Kuraray is expecting demand to peak between 2015 and 2016, just prior to such systems becoming mandatory for all ships by2017.

- Company Overviews

-

Kuraray Co., Ltd. Kashiwa Co., Ltd. Representative President Fumio Ito President Yoshiro Yamashita Headquarters 1-1-3, Otemachi, Chiyoda-ku, Tokyo 4-5-4, Takanawa, Minato-ku, Tokyo Established June 24, 1926 March 29, 1947 Capital ¥89 billion ¥200 million Principal businesses Manufacture and sales of chemicals and resins, fibers and textiles, high-performance materials, medical products and others Design, manufacture and sales of marine fire fighting systems, fire prevention equipment and others Net sales ¥376.8 billion

(March 31, 2009, consolidated)¥8.2 billion

(May 31, 2009)Number of employees 6,909

(As of September 30, 2009, consolidated)94

(As of May 31, 2009)