Overview

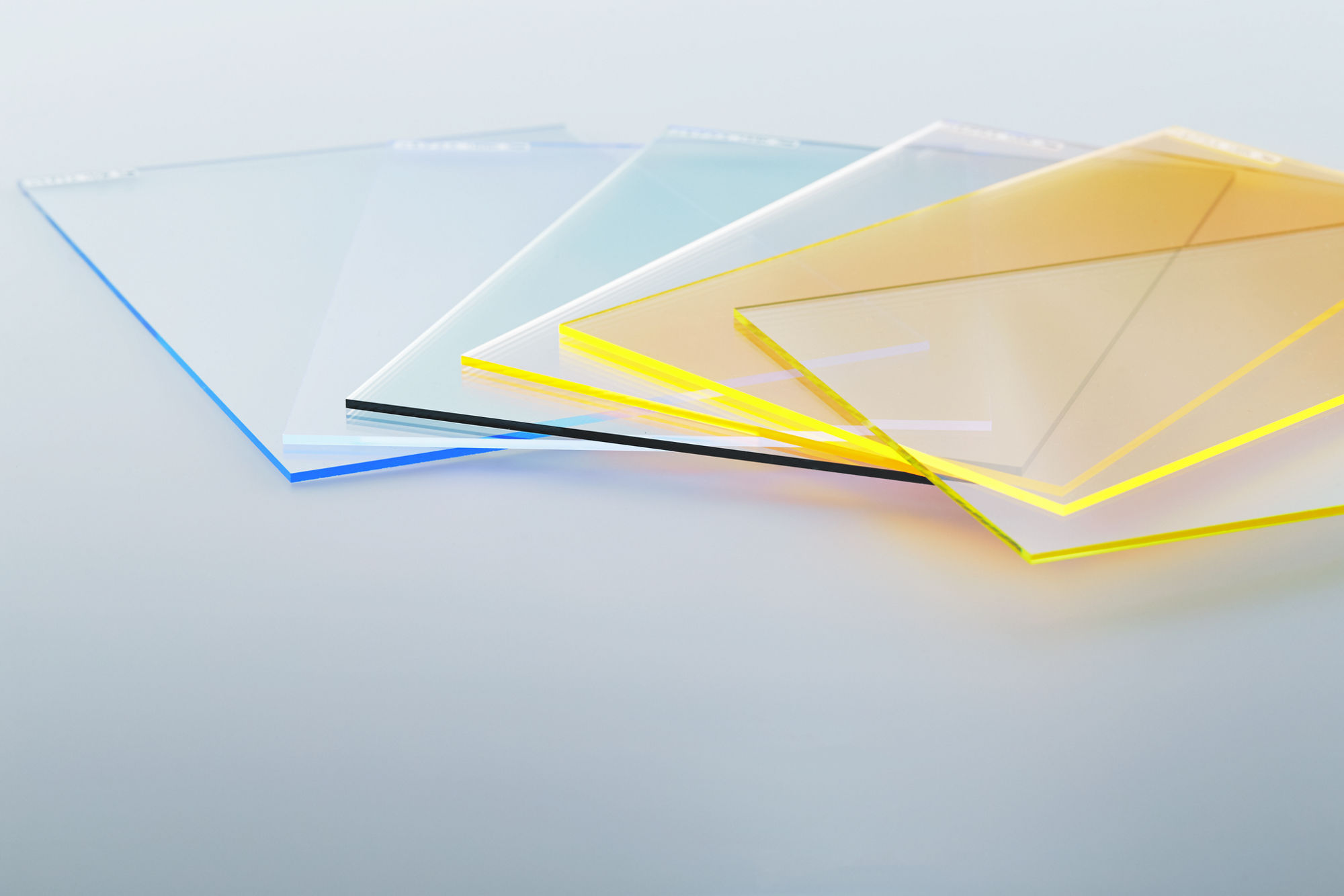

PARAGLAS™ and COMOGLAS™ are methacrylic resin sheets. Methacrylic resin is sometimes called the “queen of plastics” in Japan because of its exceptional transparency and weather resistance compared with other plastics. These features make PARAGLAS™ and COMOGLAS™ popular choices in a wide range of fields.

PARAGLAS™ is a cast sheet with excellent surface properties and high purity. It is made using Kuraray’s unique manufacturing technique of injecting a liquid monomer between two sheets of glass and directly curing it. Using batch production for easy toning, we offer a wide array of colored sheets.

COMOGLAS™ is an extruded sheet made using Kuraray’s continuous production technologies. It features outstanding thickness precision, with easy bonding and thermoforming.

Website

- Billboards and signboards for stores

- Advertisement displays and fixtures

- Frames for displays

- Building materials, water tanks, basketball backboards

- Bathtubs

- Light guides and diffusers for LED lights

- Front panels for automatic vending machines

- In-vehicle front display panels

- Transparency

Known as “the queen of plastics” for having greater transparency than even glass - Processability

Easily cut, trimmed and bonded. Can be processed into a variety of designs.

- Optical properties

Use in liquid crystal-related optical fields due to its high light-transmittance - Weatherability

Can endure extended outdoor use due to its resistance to discoloring and damage

Sheets Marketing and Sales Department,

Methacrylate Division

Kuraray Co., Ltd.

Tokiwabashi Tower, 2-6-4, Otemachi, Chiyoda-ku, Tokyo, 100-0004, Japan

Methacrylate Division

Kuraray Trading Co., Ltd.

Osaka Umeda Twin Towers North, 8-1, Kakudacho, Kita-ku, Osaka 530-8611, Japan

Methacrylate Division

Kuraray Trading Co., Ltd.

Tokiwabashi Tower, 2-6-4, Otemachi, Chiyoda-ku, Tokyo, 100-0004, Japan