News

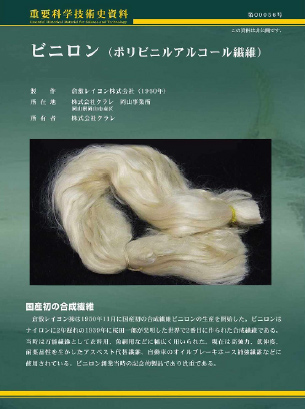

Kuraray Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo; President: Fumio Ito; "Kuraray") announces that KURALON has been recorded in the registry of important historical materials of industrial technology (Epithet: Technological Legacy for the Future) by the National Museum of Nature and Science as a valuable material that displays the development of science and technology in Japan. Developed by Kuraray in November 1950, KURALON is the first domestically produced synthetic fiber to be successfully commercialized worldwide.

Commemorating the 60th anniversary of its development this year, the registration of KURALON as a Technological Legacy for the Future is significant. Kuraray will fulfill its responsibility to preserve this worthwhile material for future generations while making every effort to create new value that plays a useful role in the development of industry.

A registration ceremony will be held at the National Museum of Nature and Science (Taito-ku, Tokyo) on Wednesday, October 6, 2010.

The synthetic fiber KURALON registered as a Technological Legacy for the Future: Registration No. 00056

The synthetic fiber KURALON registered as a Technological Legacy for the Future: Registration No. 00056

A panel on display on the second floor of the National Museum of Nature and Science's Global Gallery (Exhibition period: Tuesday, October 5, 2010 to Sunday, October 31, 2010)

Seeking to preserve and utilize valuable materials that showcase scientific and technological development in Japan, the National Museum of Nature and Science established a registration system for its important scientific and technological materials archives in 2008 with the aim of preserving these materials for generations to come. The Center displays important and successful examples of scientific and technological developments while selecting items of key significance with the intention of passing them on to future generations. The Center also selects items that have a noticeable impact on people's daily lives, the economy, society and culture. In addition to the 45 materials that have been registered to date, 27 items were registered on this occasion.

- * Information on the National Museum of Nature and Science's important scientific and technological materials archives is available at the following website:

http://sts.kahaku.go.jp/english/index.html

1.What is KURALON?

- KURALON, a synthetic fiber made from polyvinyl alcohol fibers (PVA), was developed in 1939 by a team led by Professor Ichiro Sakurada at Kyoto University. It was named Synthetic Material No. 1.

- In November 1950, Kuraray became the first company in the world to mass produce Japan's first synthetic fiber at its Okayama Factory.

- Among synthetic fibers, KURALON features the highest hydrophilic properties (3–5% moisture ratio under standard conditions), superior, ultra-high strength and weather resistance (minimal UV-related deterioration), and strong resistance to alkali and acidic substances.

2.A Wide Range of Applications

- KURALON was initially used as a replacement for the natural cotton fibers in clothing and as a replacement for hemp and cotton used in fishing nets, canvas, ropes and other items.

- Around 1960, KURALON became more widely known thanks to the high level of popularity garnered by school uniforms made from KURALON fiber and "Kuremona Fishing," which was used in fishing nets and ropes, due to its superior strength.

- Due to the emergence of polyester, nylon, acrylics and other fibers during the first half of the 1970s, the use of KURALON became specialized by taking advantage of such characteristics as its ultra-high strength, high elasticity, hydrophilic properties and chemical/weather resistance. In turn, the material was expanded for use in canvas, ropes, cheesecloth (agricultural mesh fabrics that include applications for insect repellents and light shielding), agricultural and marine materials, including nets for cultivating seaweed, and various types of foundation cloths and specialized clothing (including firefighter suits and work uniforms).

- Following these developments, KURALON was developed for applications centered on such industrial material-related areas as paper-production materials (including non-mercury alkali battery separators), automobile oil brake hoses and flame-resistant materials.

- At the same time, demand for KURALON has expanded, primarily in Europe, as a reinforcing fiber in cement to replace asbestos, which is known to have a negative impact on human health.

3.History of the KURALON Business

| April 1939 | A team led by Professor Ichiro Sakurada at Kyoto University invented a water-solvent type PVA fiber named Synthetic Material No. 1. |

|---|---|

| October 1940 | A production testing facility was established within the Okayama Factory's research laboratory. |

| May 1949 | Based on the Ministry of Commerce and Industry's decision to rapidly establish a domestic synthetic-fiber industry, Kuraray was designated as the company that would focus on the production of KURALON. |

| November 1950 | Kuraray commenced operation of a five-ton-per day facility at the Okayama Factory. |

| April 1953 | The establishment of a policy for developing a domestic synthetic-fiber industry by the Japanese government led to expanded public- and private-sector demand for applications of KURALON. |

| September 1959 | Kuraray concluded a production technology export contract with the West German company Höchst. |

| December 1959 | Kuraray concluded a production technology export contract with the French company Rhone Poulenc Industries SA. |

| April 1960 | Kuraray concluded a production technology export contract with the American company Air Reduction Company, Inc. |

| June 1963 | Kuraray signed a KURALON-manufacturing plant export agreement with Chinese National Technical Import Corp. (the plant was relocated in May 1966). |

| April 1983 | Kuraray developed KURALON fibers for use in reinforcing cement and concluded an export contract with the Swiss company Eternit (Schweiz) AG. |

| December 2008 | Kuraray reached its current annual production capacity of 40,000 tons. |

4.KURALON-Related Topics

(1) Kuraray stakes its future on corporatization of KURALON

- Kuraray resumed research on KURALON immediately after the end of the Second World War in 1946 with the aim of mass producing this material. At first, Kuraray anticipated financial assistance from the Japanese government based on its policy for developing synthetic fibers. However, Kuraray's efforts to produce KURALON experienced a major setback due to a decision by the Japanese cabinet to deny funding.

- Passionately arguing that Kuraray's initiatives were not about one company establishing a prosperous business to make a profit, but rather to restore the Japanese textile industry, then-president Soichiro Ohara negotiated directly with the governor of the Bank of Japan for the Bank's cooperation.

- Owing to such passion, Kuraray finally received joint financing from 15 banks totaling ¥1.4 billion in 1949, six times the amount of Kuraray's paid-in capital at that time. As a result, Kuraray effectively staked its existence on the KURALON business.

- Through the establishment of rayon technology, Kuraray's founding business, and the corporatization of KURALON, a corporate culture emerged that pursues the development of the Company's CSR activities as well as its proprietary technologies. Kuraray's corporate culture, which continues to this day, is expressed in the phrase: "Contributing to the World and Individual Well-being through Actions that Others are Unable to Produce."

- Unlike the commercialization of nylon and after that, polyester, which was being pursued by other companies, the corporatization of KURALON was a purely domestic endeavor since it did not require the introduction of overseas technology and used domestically produced carbide. For this reason, it can be said that this endeavor was one factor in spurring new confidence among the Japanese following Japan's loss in the Second World War.

(2) KURALON-Manufacturing Plant Was the First Factory Exported from a Western Country to China

- In 1958, a Chinese Chemical Engineering Delegation visited Japan to request the export of a KURALON-manufacturing plant for the purpose of increasing the production of consumer-use fibers. After several negotiations, a contract to export a KURALON-manufacturing plant was concluded between Kuraray and Chinese National Technical Import Corp. in Beijing in June 1963.

- Although the export of such a plant to China was extremely unusual prior to the restoration of diplomatic ties between Japan and China, it was carried out based on Soichiro Ohara's sentiment of atonement for the damage caused to the Chinese people during the Second World War. Ohara's mission behind this export was to help secure the daily life of Chinese people, who suffered from a shortage of fiber, and, in turn, to compensate for the physical devastation and psychological anguish perpetrated on the Chinese people by Japan in the past.

- However, given that there were no diplomatic relations between Japan and China at this time, and because of Japan's ties with the Taiwanese government, this proposed export became a political issue. Amid such circumstances, Kuraray held proactive consultations with the Japanese government, top members of Japanese political parties, and Western diplomats stationed in China. Thanks to these efforts, Kuraray received strong support as a key element of Japan's trading relationship with China based on the L-T Trade Agreement ("Memorandum of Understanding with regard to the Development of Long-Term Comprehensive Private-Sector Trading between Japan and China" signed in 1962) and gained approval from the Japanese government to export the plant.

- This marked the first plant to be exported to China from a Western country.

(3) Expanding Demand for KURALON as an Asbestos Substitute

- Asbestos has been widely used to reinforce cement. However, its harmful effect on human health has been recognized in recent years. Consequently, such European countries as Germany, Switzerland and Italy started to regulate the use of asbestos, a trend that has spread worldwide. In Japan, the use of asbestos has been banned since October 2004.

- As an asbestos substitute, KURALON features superior characteristics not seen in other fibers. Such features include alkali resistance (necessary for it to be mixed with cement), ultra-high strength, high elasticity, and excellent adherence with cement.

- In recent years, KURALON's superiority over other asbestos substitutes has increased, leading to expanded demand not only in Europe but also in Japan. In addition, Kuraray expects demand to grow in Southeast Asia, Eastern Europe and Central and South America.

* Image download service for the news media

We provide the ability to download images by clicking on them exclusively to the news media.

Please contact the Kuraray Corporate Communications Department if you wish to use this service.