Overview

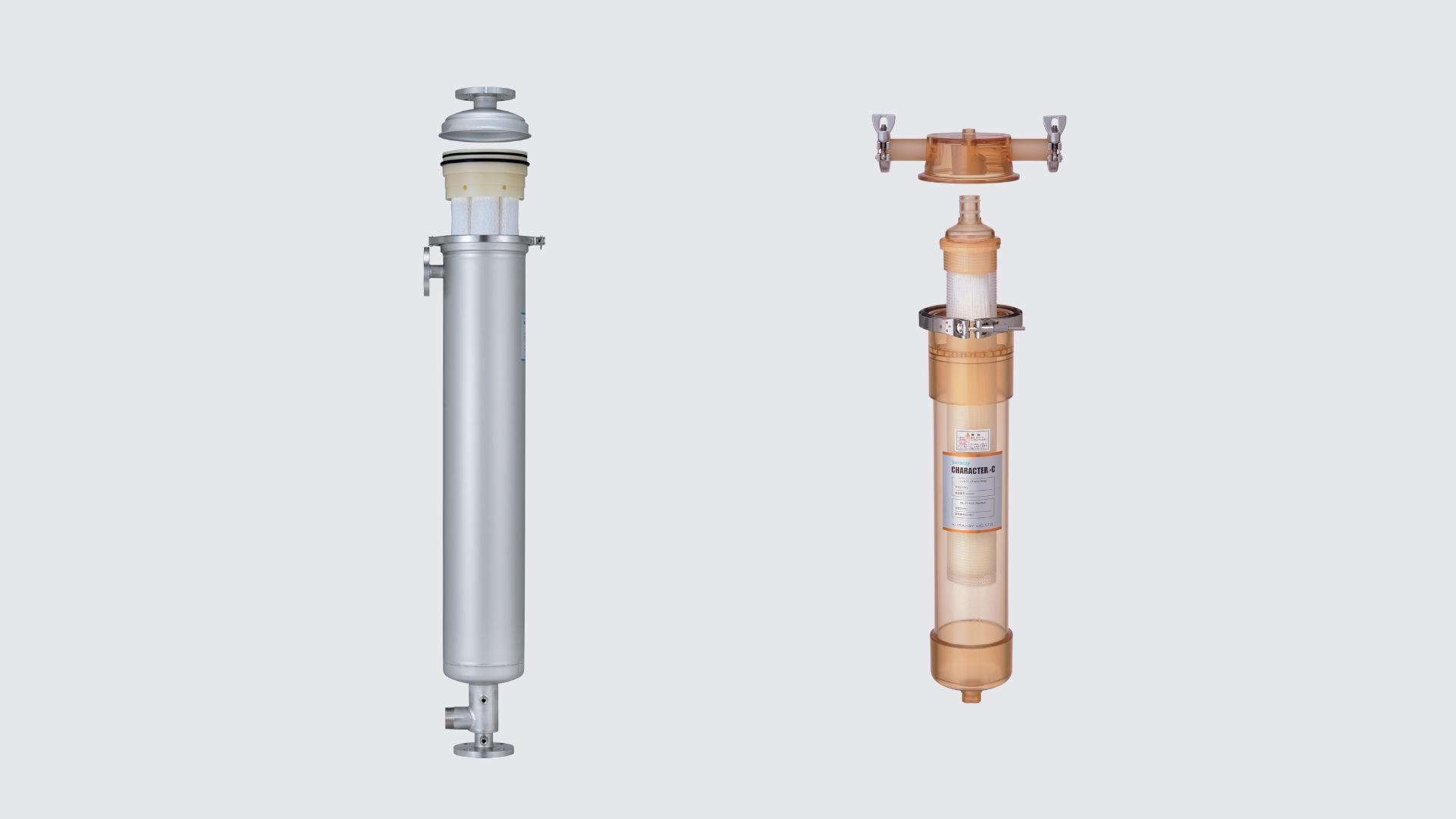

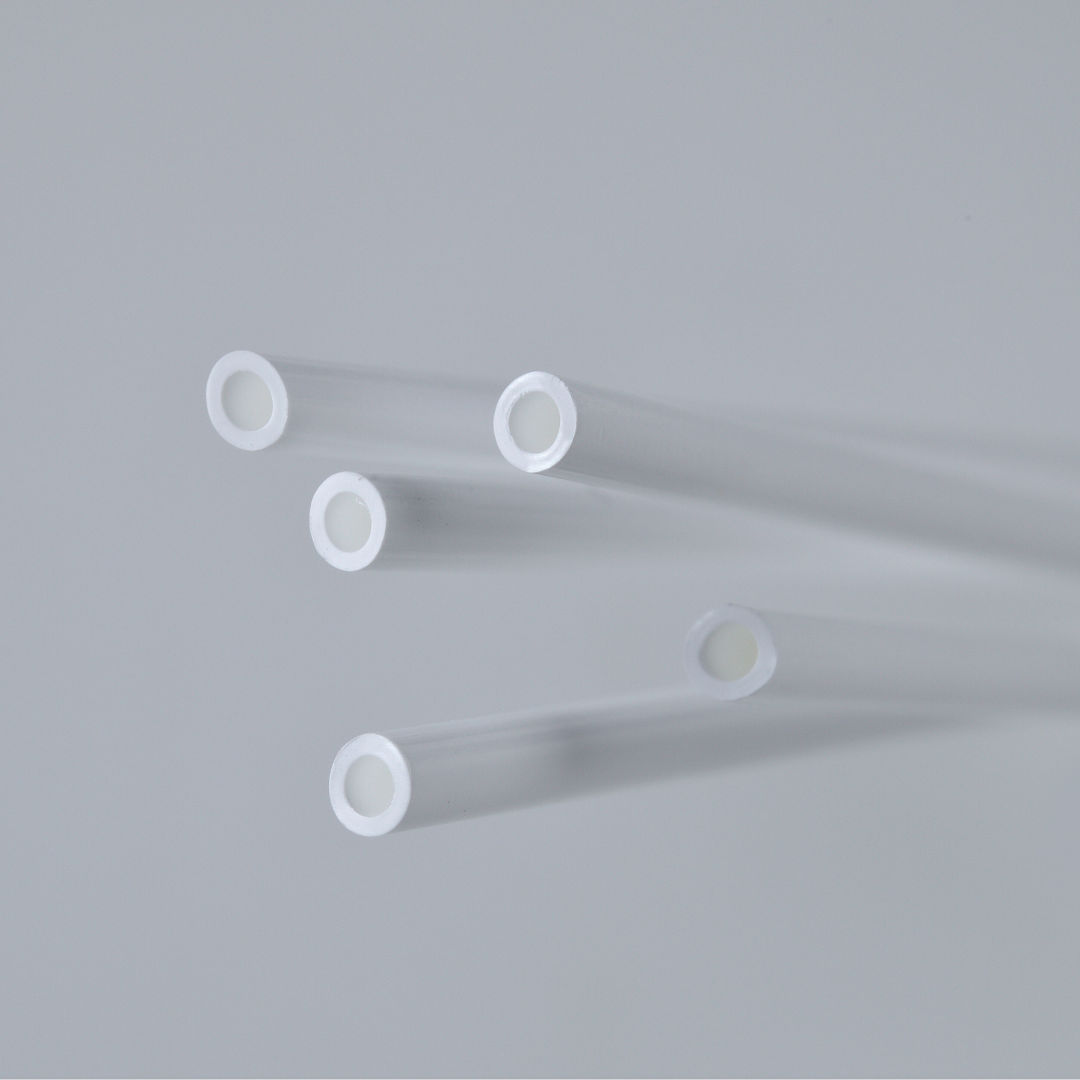

Kuraray’s hollow-fiber water treatment membranes are used for water treatment in the industrial, water supply and medical fields.

These products enable precise and efficient filtration in a wide range of settings, including manufacturing of ultra-pure water, drinking water and sterile water, and recovery of process water and wastewater.

Website

Water purification, ultra-pure water production, pure water recovery, process water/wastewater recovery, sterile (pyrogen-free) water for hospitals/ pharmaceuticals/foods, refining and fermentation of foods, medicines and other products

- High permeability

Using Kuraray’s new membrane production technology, FG module shows three times higher permeability than Kuraray’s existing products. - High strength, high chemical resistance

Kuraray’s proprietary hydrophilized polyvinylidene fluoride (PVDF) membranes are extremely durable. - Applicable to high-turbidity water

Due to its one end free structure with a center distributor, FG module can handle raw water with high turbidity.

- High raw water recovery rate

Adoption of the air backwash method enables operation with a high raw water recovery rate. - Compact design and reduced costs

Does not require the use of tanks for backwashing or pumping, helping to reduce equipment costs - Extensive product lineup

Products are made of PVDF and polysulfone (PSF) as raw materials.

Environmental Business Sales Department

Environmental Sales Department

Kuraray Co., Ltd.

Tokiwabashi Tower, 2-6-4, Otemachi, Chiyoda-ku, Tokyo, 100-0004, Japan

TEL: +81-3-6701-1655