KURARAY POLYOL and Diols

- General name

- (3-Methyl-1.5-Pentanediol (MPD), 1,9-Nonanediol (ND))

A raw material for polyurethanes. Offers improved strength and flexibility.

Kuraray offers synthetic diols, 3-methyl-1,5-pentanediol (MPD) and 1,9-nonanediol (ND). These products are produced with Kuraray’s proprietary synthesis technology. A variety of derivatives from these diols are also available under the name KURARAY POLYOL. MPD is an isomer of 1,6-hexanediol and hexylene glycol, its methyl branch imparts many distinctive properties to the derived polymers, including low viscosity, hydrolysis resistance, wide compatibility and good softness. Polyurethane and polyester resins are key applications for these diols.

Applications

MPD, ND

Plasticizers: General plasticizer, special plasticizer

Resin raw materials: Polyester resin, epoxy resin, polyurethane resin, and other raw materials and modifiers

KURARAY POLYOL

Polyurethane: Inks, synthetic leather, elastomers, paint adhesives, coatings, foams

Characteristics

KURARAY POLYOL

High hydrolysis resistance: Enhanced durability

Liquid state, low viscosity: Offers excellent handling properties with many liquid grades at room temperature

High flexibility: Excellent flexibility

Compatibility with other polyols: Compatible with not only general-use polyester polyol, but also polyether polyol.

Standard grades and properties

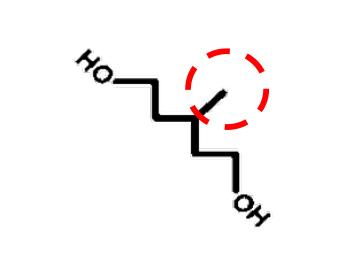

Diol MPD

- Chemical name:

- 3-Methyl-1,5-pentanediol

- Basic properties

-

- Appearance:

- Colorless liquid

- Melting point:

- < -50ºC

- Viscosity (20ºC)

- 173mPa・s

- Boiling point:

- 250ºC

- Flash point:

- 143ºC

- Applications

-

- Polyurethanes (polyols, chain extenders)

- Polyester

- UV monomer, oligomer

- Inks

- Non-crystallinity

- Hydrophobicity

- Characteristics

-

- Low viscosity (handling)

- Flexibility

- Transparency

- Compatibility

- Hydrolysis resistance

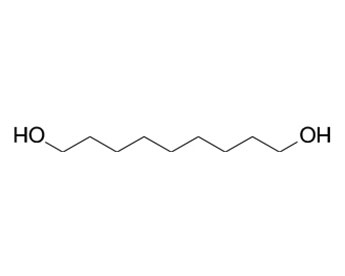

Diol ND

- Chemical name:

- 1,9-Nonanediol

- Basic properties

-

- Exterior:

- White solid

- Melting point:

- 46ºC

- Viscosity (60ºC)

- 33mPa・s

- Boiling point:

- 166ºC

- Flash point:

- 162ºC

- Applications

-

- Polyurethanes (polyols, chain extenders)

- Polyester

- UV monomer, oligomer

- Long chain

- Odd main chain

- Appropriate crystallinity

- Characteristics

-

- Hydrolysis resistance

- Melting point is relatively high, but viscosity of 60ºC is the same as acetone

Polyols: KURARAY POLYOL (overview)

| Type | Grade (series) | M.W. | Exterior 25ºC |

Overview and features | Application examples (including PU) |

|---|---|---|---|---|---|

| Polyester polyols | P-**10 | 500 ~ 6,000 | Liquid | General-purpose grade | Printing inks TPU Synthetic leathers PU textile (spandex) |

| F-**10 | 500 ~ 3,000 | Three functions, heat resistance | |||

| P-**20 | 500 ~ 2,000 | Wax | Water resistance Adhesiveness Acid resistance |

PUD Metal paint/coating |

|

| P-**30 | Liquid | ||||

| P-**50 | 2,000 | Liquid | Flexibility Water resistance Acid resistance, alkalinity Bio |

TPU coating Inks |

|

| Polycarbonate polyols | C-**90 | 500 ~ 3,000 | Liquid | Flexibility Water resistance Low temperature property |

PUD Synthetic leathers Electronic components |

Characteristics of polyurethane depending on polyols

KURARAY POLYOL

- ++Very Good

- +Good

- -Poor

- --Very Poor

| Polyol | Ether type | Ester type | Carbonate type | ||||||

|---|---|---|---|---|---|---|---|---|---|

| PPG | PTMG | PBA | P-xx10 | P-xx50 | P-xx11 | P-xx20 | PHC | C-xx90 C-xx50 |

|

| Softness | ++ | + | + | ++ | ++ | + | -- | - | + |

| Low temp. softness | ++ | + | - | ++ | ++ | - | -- | - | ++ |

| Water resistance | + | + | -- | + | ++ | + | ++ | ++ | ++ |

| Acid resistance | + | + | -- | + | ++ | ++ | ++ | ++ | ++ |

| Alkali resistance | + | + | -- | + | ++ | + | ++ | ++ | ++ |

| Transparency | + | + | -- | ++ | ++ | ++ | ++ | -- | ++ |

| Solvent resistance | -- | -- | + | - | + | + | ++ | + | + |

| Heat resistance | -- | -- | ++ | + | + | + | ++ | ++ | + |

| UV resistance | -- | -- | ++ | ++ | ++ | + | + | ++ | ++ |

| Adhesiveness | -- | -- | + | ++ | + | ++ | ++ | - | + |

Related website

Contact us

Click here for inquires (KURARAY POLYOL and Diols)- Chemicals Marketing and Sales Department, Isoprene Chemicals Division

- Tokiwabashi Tower, 2-6-4, Otemachi, Chiyoda-ku, Tokyo, 100-0004, Japan

Tel.: +81-3-6701-1709

Fax.: +81-3-6701-1646